Setting Up Product Inventory

Note: This topic is relevant for static, easy upload and dynamic products.

uStore provides you an inventory management feature that enables you to keep track of the stocks of your static and dynamic products. uStore inventory management settings help you control your on-shelf inventory, set a safety inventory level and display product inventory information in the storefront.

Inventory triggers

You can set up rules to be informed about inventory changes. There are two events available for setting up inventory triggers:

-

Inventory Changed: A notification is sent for every product purchase.

-

Inventory Level Is Low: A notification is sent when the on-shelf inventory reaches the predefined limit.

You set up triggers at Presets > Trigger Setup. To learn more about how to set up triggers, see Setting Up Triggers.

Inventory reports

The Inventory Levels report provides the current inventory levels of all products that are tracked.

To generate the Inventory Levels report, go to Presets > Reports.

To learn more about uStore reports, see Generating Reports.

To set up inventory management parameters:

-

In the Product Setup page, click Inventory Setup.

The Inventory Setup page is displayed.

-

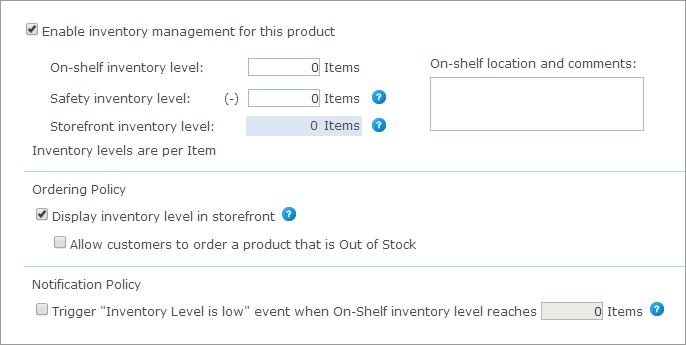

Select the Enable inventory management for this product checkbox.

-

In the On-shelf inventory level field, enter the number of items (or packs) that are currently in stock.

The On-shelf inventory level is updated only after a customer completes the checkout process or, if an approval process is defined, the purchase is approved by the order approver. On-shelf inventory level is displayed in the Order Details page.

Make sure to update the on-shelf inventory level when you get new stock.

-

If required, in the Safety inventory level field, set the minimum number of items (or packs) that should always be kept in stock. You can fill in a negative number to enable customers to order more items than the number of items that are available according to the On-shelf inventory level.

Notice that the Storefront inventory level is automatically calculated and displayed. This value represents the number of items (or packs) that are available for purchase in the storefront. The value displayed is the result of the following calculation:

Storefront inventory level = [On-shelf inventory] - [Safety inventory]

This is the inventory level that is displayed in the storefront.

-

To enable customers to see the availability of the product, which is the current storefront inventory level, in the Ordering Policy section select the Display inventory level in storefront checkbox.

-

Once the above checkbox is selected, you can enable users to order the product when it is out of stock by selecting Allow customers to order a product that is Out of Stock.

If you enable customers to order products that are out of stock, product delivery dates may be affected. In addition, customers will be able to purchase the product even if the on-shelf inventory reached its limit.

If the Display inventory level in storefront option is not selected, uStore still updates the on-shelf inventory and the backoffice inventory when the product is purchased, but the inventory status does not appear in the storefront.

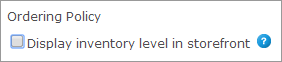

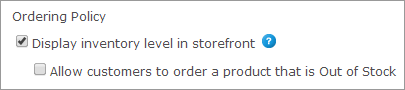

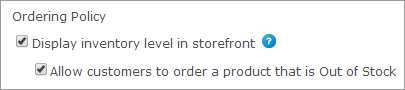

Examples of ordering policy selections

Examples of ordering policy selections

-

uStore tracks inventory, but storefront inventory levels are not displayed.

-

Storefront inventory levels are displayed in the storefront, but customers cannot order products that are out of stock. Customers can select the product and purchase it later, when the inventory is renewed.

-

Storefront inventory levels are displayed in the storefront and customers can order products that are out of stock. Product delivery dates may be delayed

-

-

To be notified when the On-Shelf inventory level reaches predefined limit, under Notification Policy select the Trigger "Inventory Level is low" event when On-Shelf inventory reaches, and define the number of items that will trigger the notification.

The notification is sent out at once.

-

Click Save and place the product online.

Notes:

-

Dynamic recipients are counted by adding up all recipients that requested to be produced, and not the actual number of recipients that eventually were produced. For example, if a recipient was skipped for any reason during production, it will still be counted as inventory used.

-

Products using inventory are returned to stock when an order is cancelled.